In the world of inventory management and logistics, the concept of Economic Order Quantity (EOQ) plays a pivotal role in optimizing ordering processes and reducing costs. This mathematical model, first introduced by Ford W. Harris in 1913, has since become a cornerstone in supply chain management, offering a systematic approach to determining the ideal order quantity to minimize total inventory costs.

The EOQ calculation is particularly valuable for businesses that deal with perishable goods, fast-moving consumer goods, or products with short lifespans. By finding the sweet spot between production/procurement costs and holding costs, businesses can achieve significant cost savings and improve overall operational efficiency. This model considers various factors such as demand rate, ordering costs, carrying costs, and production lead time to calculate the optimal order quantity.

Understanding the EOQ Formula

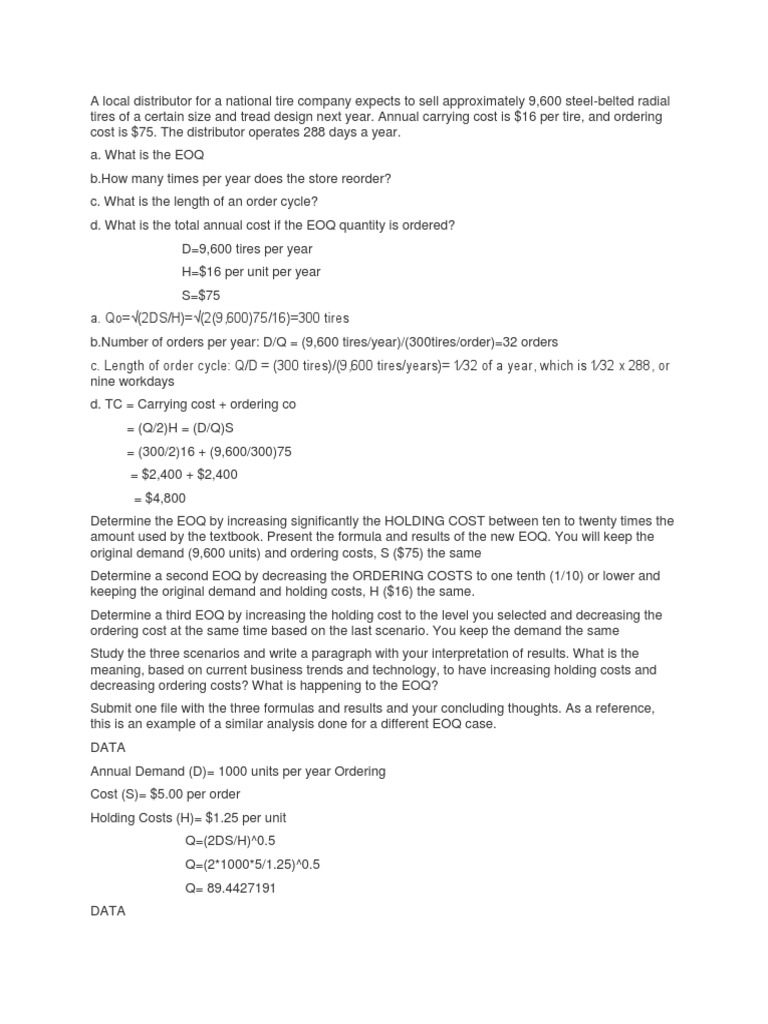

The Economic Order Quantity (EOQ) is a formula used to determine the optimal order quantity for a given product, considering various costs associated with ordering and holding inventory. The formula is as follows:

EOQ = √[2DS/H]

Where:

- D = Annual Demand (in units)

- S = Ordering Cost per Order

- H = Holding Cost per Unit per Year

This formula provides a mathematical representation of the balance between ordering costs and holding costs. By plugging in the relevant values for demand, ordering costs, and holding costs, businesses can calculate the EOQ and make informed decisions about their inventory management.

Factors Influencing EOQ

The EOQ calculation is influenced by several key factors, each of which can significantly impact the optimal order quantity. Understanding these factors is crucial for businesses to make accurate calculations and effective inventory management decisions.

Demand Rate

Demand rate, or annual demand, is a critical factor in EOQ calculation. It represents the total quantity of a product that a business expects to sell or use in a year. A higher demand rate generally leads to a higher EOQ, as it indicates a need for more inventory to meet customer demands.

For example, consider a business that sells laptops. If the annual demand for laptops is 10,000 units, the EOQ calculation will be influenced by this demand rate. A higher demand rate would result in a larger EOQ, ensuring sufficient inventory to meet customer needs without excessive holding costs.

Ordering Costs

Ordering costs refer to the expenses incurred each time a business places an order. These costs include administrative fees, procurement fees, and any other costs associated with the ordering process. Higher ordering costs can influence the EOQ calculation by making it more cost-effective to place larger orders less frequently.

Take the laptop business as an example again. If the ordering cost per order is $50, and the holding cost per unit per year is $10, the EOQ calculation will consider these costs. By reducing the number of orders placed, the business can minimize ordering costs and optimize its inventory management strategy.

Holding Costs

Holding costs, also known as carrying costs, are the expenses associated with storing and maintaining inventory. These costs include warehousing, insurance, obsolescence, and other related expenses. Holding costs can significantly impact the EOQ calculation, as higher holding costs may encourage businesses to order smaller quantities more frequently to minimize storage expenses.

Continuing with the laptop example, if the holding cost per unit per year is $10, and the ordering cost per order is $50, the EOQ calculation will aim to find a balance between these two costs. By optimizing the order quantity, the business can reduce both ordering and holding costs, leading to overall cost savings.

Production Lead Time

Production lead time, or the time between placing an order and receiving the inventory, is another crucial factor in EOQ calculation. Longer lead times can impact the optimal order quantity by increasing the risk of stockouts and the need for larger safety stocks.

For instance, if the laptop business has a long production lead time of 6 months, it may need to place larger orders to ensure sufficient inventory during this period. This consideration is especially important for businesses operating in industries with unpredictable demand or long supply chains.

Benefits of EOQ Calculation

Implementing EOQ calculations offers several advantages to businesses, particularly those with complex supply chains or high inventory costs. By optimizing the order quantity, businesses can achieve significant cost savings and improve their overall operational efficiency.

Reduced Inventory Costs

One of the primary benefits of EOQ calculation is the reduction of inventory costs. By finding the optimal order quantity, businesses can minimize both ordering and holding costs. This results in significant cost savings, as excess inventory can be costly to store and maintain, while frequent small orders can lead to higher administrative expenses.

Improved Cash Flow

EOQ calculation also contributes to improved cash flow management. By optimizing the order quantity, businesses can reduce the need for excessive inventory, freeing up cash that would otherwise be tied up in stock. This improved cash flow can be reinvested into other areas of the business, such as research and development or marketing efforts.

Enhanced Customer Service

EOQ calculation plays a crucial role in enhancing customer service. By ensuring that the optimal order quantity is maintained, businesses can avoid stockouts and meet customer demands consistently. This leads to improved customer satisfaction and loyalty, as customers can rely on the business to have the products they need when they need them.

Efficient Supply Chain Management

EOQ calculation is an essential tool for efficient supply chain management. By optimizing the order quantity, businesses can streamline their procurement processes, reduce lead times, and improve overall supply chain efficiency. This can result in faster delivery times, reduced transportation costs, and a more responsive supply chain.

Challenges and Limitations

While EOQ calculation is a powerful tool for inventory management, it does come with certain challenges and limitations that businesses should be aware of.

Assumptions and Simplifications

The EOQ calculation is based on several assumptions and simplifications that may not always hold true in real-world scenarios. For instance, the calculation assumes constant demand and costs, which may not always be the case in dynamic business environments. Additionally, it assumes that lead times are predictable, which can be challenging in industries with fluctuating supply chains.

Dynamic Business Environments

Businesses operate in dynamic environments where demand, costs, and market conditions can change rapidly. As a result, the EOQ calculation may need to be adjusted frequently to account for these changes. This can be a challenging task, especially for businesses with complex supply chains or those operating in volatile markets.

Balancing Costs and Service Levels

EOQ calculation aims to balance ordering and holding costs, but it may not always align with a business’s service level objectives. For example, a business may prioritize customer service and rapid delivery, which could lead to higher holding costs. In such cases, the EOQ calculation may need to be adjusted to accommodate these service level requirements.

Real-World Applications

EOQ calculation has found extensive applications across various industries, each with its unique challenges and requirements. Let’s explore a few real-world examples to understand how EOQ is applied in practice.

Retail Industry

In the retail industry, EOQ calculation is crucial for optimizing inventory management, especially for fast-moving consumer goods. Retailers use EOQ to determine the optimal order quantity for products like groceries, household items, and fashion accessories. By finding the balance between ordering and holding costs, retailers can ensure they have sufficient stock to meet customer demands while minimizing excess inventory.

Manufacturing Sector

Manufacturers also leverage EOQ calculation to optimize their inventory management processes. By determining the optimal order quantity for raw materials, components, and finished goods, manufacturers can reduce lead times, minimize production disruptions, and improve overall efficiency. EOQ calculation helps manufacturers strike a balance between maintaining sufficient inventory levels and avoiding excessive holding costs.

Healthcare Sector

The healthcare sector, with its critical need for timely and accurate inventory management, also benefits from EOQ calculation. Hospitals and healthcare providers use EOQ to determine the optimal order quantity for medical supplies, pharmaceuticals, and equipment. By optimizing inventory levels, healthcare facilities can ensure they have the necessary supplies to provide quality care while reducing waste and excess inventory costs.

Future Implications and Trends

As businesses continue to embrace digital transformation and adopt advanced technologies, the future of EOQ calculation holds exciting possibilities. The integration of artificial intelligence (AI) and machine learning (ML) into inventory management systems is expected to revolutionize EOQ calculation, making it even more accurate and responsive to dynamic business environments.

AI and ML Integration

AI and ML algorithms can analyze vast amounts of data, including historical sales data, market trends, and supply chain dynamics, to predict demand and optimize EOQ calculations. By leveraging these technologies, businesses can make more informed decisions, adjust order quantities in real-time, and improve overall inventory management efficiency.

Dynamic EOQ Models

The development of dynamic EOQ models that can adapt to changing market conditions and supply chain fluctuations is another future trend. These models will enable businesses to make more accurate predictions and adjust their inventory strategies accordingly, ensuring they remain competitive and responsive to market demands.

Integration with Supply Chain Networks

EOQ calculation is likely to become more integrated with supply chain networks, allowing for a more holistic approach to inventory management. By connecting with suppliers, distributors, and retailers, businesses can optimize their entire supply chain, reducing lead times, improving collaboration, and achieving greater cost efficiencies.

Conclusion

Economic Order Quantity (EOQ) calculation is a powerful tool for businesses to optimize their inventory management processes and reduce costs. By understanding the factors influencing EOQ and implementing the calculation effectively, businesses can achieve significant benefits, including reduced inventory costs, improved cash flow, enhanced customer service, and efficient supply chain management.

While EOQ calculation comes with certain challenges and limitations, the future of inventory management looks promising with the integration of AI, ML, and dynamic models. These advancements will enable businesses to make more accurate predictions, adapt to changing market conditions, and stay competitive in dynamic business environments.

By staying informed about the latest trends and technologies in inventory management, businesses can leverage EOQ calculation to its fullest potential, driving operational excellence and long-term success.

How often should EOQ calculations be updated?

+EOQ calculations should be updated periodically to account for changes in demand, costs, and market conditions. As these factors fluctuate, it is crucial to reevaluate the EOQ to ensure it remains optimal. The frequency of updates may vary depending on the industry and the business’s specific circumstances, but as a general guideline, quarterly or semi-annual reviews are recommended.

Can EOQ calculation be applied to all types of inventory?

+EOQ calculation is most effective for inventory with stable and predictable demand patterns. While it can be applied to various types of inventory, it may not be as beneficial for products with highly volatile or unpredictable demand. In such cases, alternative inventory management strategies, such as Just-In-Time (JIT) or Vendor-Managed Inventory (VMI), may be more suitable.

What are some common challenges in implementing EOQ calculation?

+Implementing EOQ calculation can present several challenges, including accurately estimating demand, identifying and quantifying costs, and managing dynamic business environments. Additionally, ensuring buy-in from stakeholders and aligning EOQ with overall business strategies can be complex. Overcoming these challenges requires a thorough understanding of the business, its processes, and its goals.